In today’s technologically-based society, manufacturing has evolved from the small town textile mills and factories of yesteryear and has moved toward an advanced, automated, interdisciplinary field.

As demonstrated by the focus of the Institute of Emergent Issues forum last month on manufacturing, as well as the forum being hosted Monday, universities are taking more interest, and are playing larger roles in the economic success of not only North Carolina, but the United States as a whole.

This is evident right here at N.C. State, where student-formed companies such as Open Hardware Makerspace, Wolfpack Motorsports and NCSU EcoCar2 are attempting to make an impact.

Open Hardware Makerspace provides the tools and expertise to make manufacturing on campus more accessible. Started in August 2011, Open Hardware Makerspace has offered training from professionals in an on-campus workshop students can use to build their designs.

“We are trying to provide access to equipment for fabrication and for experimentation,” John Turner, former president of Open Hardware Makerspace and senior in mechanical engineering, said. “And having hands-on experience building things makes you a better designer.”

In only a year and a half, Open Hardware Makerspace has acquired $10,000 worth of equipment. It focuses on additive manufacturing, a form of sustainable manufacturing in which fewer materials are used, such as 3D printing. “[Manufacturing] is no longer a brute force, a lot of it is high tech and high skill now,” Turner said.

Turner also said that with this shift in manufacturing, he thinks the organization will eventually bridge between the arts and manufacturing.

EcoCar2, another manufacturing organization on campus, works to transform a standard car into a hybrid. The team at EcoCar2 studies not only the theory behind hybrid cars but also the processes used by vehicle companies such as Chevy and Ford.

“Big car makers are working on these types of cars,” Evan Connell, a senior in mechanical engineering, said. Connell joined Ecocar2 as a part of his independent study and senior design.

Currently, the team is designing brackets, the connecting pieces from the old car to the new hybrid, for a custom fit. The team, besides making a more environmentally friendly car, is graded on consumer satisfaction with their final product.

“This is exactly what GM or Ford would be doing,” Ryan Springer, a senior in mechanical engineering and control team member, said. He believes that the importance of communication and business is an increasingly important factor in success in the manufacturing world.

These student run organizations are pushing the technological envelope and making manufacturing not about the manual work, but about the thought put into each design.

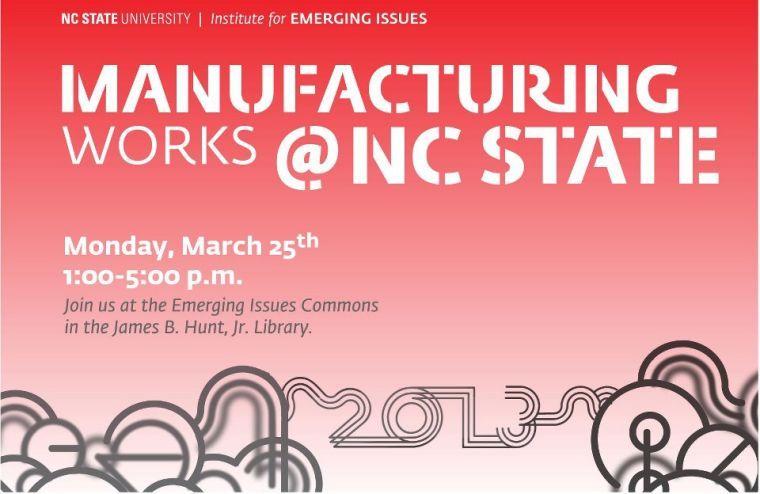

ManufacturingWorks@NCState will take place:

When: Monday, March 25, 1-5 p.m.Where: Hunt Library Institute for Emerging Issues Multi-Purpose Room (Second Floor)

Who will be there?

Business experts and leadersMarshall Brain, founder of HowStuffWorksAlumni in the manufacturing field from companies like IBM, Fujifilm Biotechnologies, GoPro and the North Carolina Technology Association

Why is it important?

North Carolina’s leading economic machine is the manufacturing industry.Students will have the opportunity to interact with panelists and network with industry representatives.

Get Registered (recommended, but not required):

http://manufacturingworksncstate.eventbrite.com/