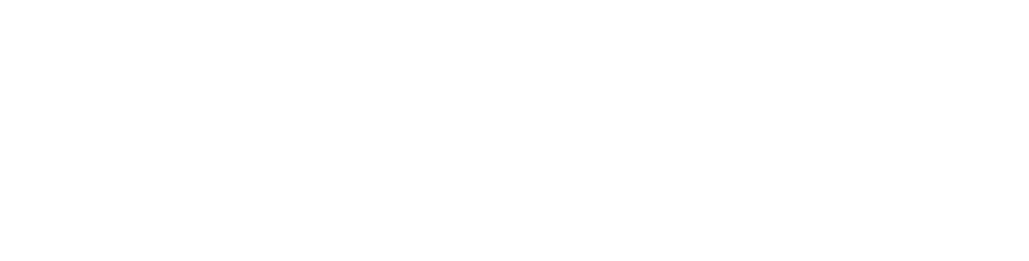

Binil Starly, the director of industrial engineering and systems engineering lab for Engineering Biological Tissue Systems at N.C. State, is leading research into 3-D printing technology that could lead to huge advances in the future, including the production of human organs.

The applications of 3-D printing for biomedical purposes are almost endless. One of the main areas involves the testing of drugs. Currently, researchers grow liver cells and insert the drugs that are being tested into the liver to see if the drug is safe and efficient.

The problem with this method, Starly said, is the testing is all done two-dimensionally in animal cells, but human cells grow three-dimensionally in the body.

These studies are also ruling out drugs that could potentially be useful to humans, according to Starly.

Starly said Penicillin was an example, saying that certain influential drugs used today wouldn’t make it through the long legal acceptance process.

“If [Penicillin] were to be invented and tested today, it would not go through, because it is lethal to pigs,” Starly said. “Drugs can be lethal to animals, but not to humans, so we are losing out on so many drugs.”

Bioprinting allows physicians and researchers to create complex human molecules, which is beneficial for testing purposes. However, there are problems associated with manufacturing.

“As manufacturing engineers, our goal is to produce these molecules in large quantities reliably,” Starly said. “If we make 100, every single one of the 100 must be quality approved, and scientists have to trust this. Since we are dealing with living molecules, there is complexity involved, as opposed to manufacturing metals. How do you quality proof something that is living?”

Another application of bioprinting involves testing drugs as they relate to space travel, Starly said.

NASA is interested in testing the effectiveness of drugs in space. It would be impossible, however, to send animals into space to complete testing. Starly said we could create a liver device, perhaps containing 100 one-inch by one-inch squares, each with the ability to test a different drug.

This way, NASA would be able to test multiple drugs at once, and save money on expensive equipment and training.

Starly said the most exciting application of this technology might not have to do with organ printing.

In the Netherlands researchers are working on making beef and leather in a lab, according to Starly.

Growing beef is essentially making a mixture of muscle and fat, but instead of using it for medical purposes, it would be used for human consumption.

Because producing meat this way involves the creation of living tissue, there are still many problems to be faced before people will ever see this kind of meat in the store, but the research is surging forward.

In addition, if it were possible to create skin using a bioprinter, it would open up the possibilities of creating all sorts of different textiles, including leather.

“Right now, we have all this media frenzy on organ printing, but that might be a little bit too vague,” Starly said. “Our immediate concern might be associated with creating tissue and creating leather because if we can’t do those things, we certainly can’t create something as complex as a human organ.”

The Research Triangle Park area is known for its innovation, especially when it comes to agriculture and livestock-related biotechnology, according to Starly.

Starly said he is excited by the possibilities, and how this could bring more industry to the area.

“Creating stem cells could be in the future, and for this, you need an industry to produce the necessary raw materials,” Starly said. “This would increase local industry and get more people involved with the process. This research must be done now, for we are hoping that five years down the road, the applications will be ready and will attract industry and more funding.”